Direct Thermal Labels

Direct thermal paper has the special heat sensitive powder, thus when do printing it does not need the thermal transfer ribbon. So it can avoid the waste of ribbon and save a lot of cost.

Crystal can provide several different types of direct thermal paper stickers. All have the good features for waterproof, resistance to oil and chemical.

1. Normal direct themal paper sticker

2. Detachable two layer thermal paper sticker

3. Syethnic direct themral paper sticker

4. PP direct thermal paper sticker

Direct thermal labels offer high-quality barcode printing for numerous applications. Unlike thermal transfer printing, direct thermal printing does not require a thermal ribbon. Instead, the process uses heat to start a chemical reaction within the label itself. This reaction creates the printed image.

Our Direct Thermal Products all have a heat sensitive coating on the face stock which enables these products to be imaged with a barcode printer and does not require a ribbon. Our product offering includes various face stocks from paper to BOPP film. These products cover a wide range of applications and can be manufactured with a multitude of adhesives to meet our customers’ requirements. Non Top Coated Paper – Our Economy Paper labels utilize a paper base stock to which a thermal coating has been applied. Top Coated Paper – Our Premium Paper labels are smooth, bright, white paper with a high sensitivity thermal coating. Direct Thermal BOPP Film – A durable, high sensitivity, 3 mil direct thermal polypropylene film (BOPP) for use with high speed thermal printers. Browse through our standard offering of online labels below and receive a quality product combined with excellent cost savings.

Why Use Direct Thermal Labels?

Doesn’t require a ribbon

Perfect for short term usage

Works in Industrial, Desktop, and Mobile Printers

Great for shipping labels

Why Not?

Will fade overtime

Only prints in black and white

Can scuff and smudge

How Does Direct Thermal Work?

Unlike other types of labels, direct thermal printing does not require ink, toner, or a thermal ribbon. The only media that passes through the printer is the label paper itself. The heat of the print head, combined with the chemical composition of the thermal paper results in a chemical reaction that produces the desired image.

Overall, direct thermal printing is great for most barcode and identification needs. However, direct thermal prints do degrade over time, especially with exposure to light, heat, or reactive chemicals. In cases that require archival-quality, permanent identification, thermal transfer printing is the best choice. However, for barcodes that must remain readable for 6 months or less, direct thermal printing offers an ideal choice as far as efficiency, quality, and cost-effectiveness.

Types of Direct Thermal Labels Available

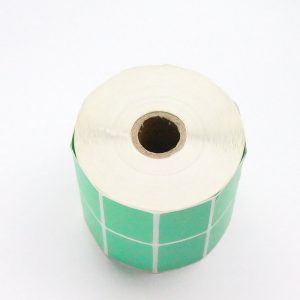

One of the things that differentiates RYLabels is the wide range of labels that we keep in stock. In the family of direct thermal labels, we offer both roll and fanfold style labels. The majority of our labels are made of paper however, we do have some direct thermal labels that are made with polypropylene. We also offer our direct thermal labels in different colors. If you can’t find a color you are looking for, please contact us.

In addition to stocking different roll sizes, we also offer our direct thermal labels in several different types of adhesive. For your standard, ambient temperature applications, our all-temp adhesive is suitable. If your environment goes below freezing, we would highly recommend purchasing our freezer grade direct thermal labels. Finally, we also offer a removable adhesive for those applications that require it.

Of all of our labels, easily the most popular is our 4×6 labels. The reason for that is our vertically integrated manufacturing and supply chain. The fact that we coat, slit, and cut our thermal paper in-house and make our own adhesive, allows us to offer you the lowest prices in the industry.